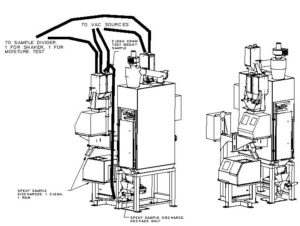

Reduce the bottleneck caused by manual hands-on grain grading with the MCi AUTO KICKER and handle more trucks per hour!

Reduce the bottleneck caused by manual hands-on grain grading with the MCi AUTO KICKER and handle more trucks per hour!

How much time does one really spend handling a grain sample? Incoming grain goes through the probe, to the collection box, to the sample divider, then half goes to the moisture tester, the other half to the dockage scale, then to the sieving process, to the dockage scale again, then the clean grain goes to the moisture tester for test weight (Wheat, Barley), and then to the protein analyzer. Then it takes time to collect all that data and to enter it on the ticket! It’s time consuming, labor intensive, inefficient and costly!! Let the MCi AUTO KICKER help with that!!

There is a better way!

The MCi AUTO KICKER connects directly to your grain probe allowing direct deposit of the sample into the MCi AUTO KICKER. The MCi AUTO KICKER immediately processes that sample and analyzes it for dockage or fm, shrunk or broken kernels, moisture, test weight and temperature, and with the optional NIR/NIT unit installed in the system, protein, oil and starch (depending on the grain calibration functions) – all in one process! No human hands need to touch that portion of the sample! The results are displayed on the computer screen and then can automatically transfer the results to your scale ticket software, thus eliminating manual entry and mistakes. Imagine your time savings on each sample! These quick and accurate results also help with more precise binning. You can quickly know where to bin your grain based on it’s quality, if so desired.

Your whole scaling and grading operation will run smother and more efficiently with the MCi Auto Kicker. Our customers tell us that they have reduced their grading staff to one person, even through peak harvest times! This lets them use the extra staff someplace else in their facility, which helps to make their operation run more smoothly.